Crystal quality of MoS2 from atomic resolution microscopy

November 04, 2019 - New research by a group from the University Toulouse (France), Jena, and Ulm (Germany), as well as the National Institute for Materials Science Tsukuba (Japan) indicates that conventional CVD MoS2 is suitable for applications which were so far limited to exfoliated samples. Individually exfoliated monolayers of transition metal dichalcogenides (TMDs) such as from bulk MoS2 are typically only tens of micrometers in lateral size. The availability of high quality monolayer MoS2 films grown by chemical vapor deposition (CVD) is often are critically needed for practical applications. The HRTEM investigation demonstrates high crystalline quality of CVD-grown MoS2 comparable to exfoliated samples.

High quality monolayer transition metal dichalcogenides (TMDs) such as MoS2 and WSe2 are semiconductors with a direct bandgap in the visible to near-infrared region [1, 2]. Their strong light matter interaction and fascinating transport properties allow the application in various future devices [3-6]. The fabrication of those devices usually requires encapsulation in hexagonal boron nitride (hBN) to protect the band structure from external influence [7-11]. Many applications require in addition hundreds of micrometers in lateral size and a large number of flakes on the same substrate or even continuous films [12-14].

Usually, previous studies had considered only exfoliated TMDs for their fundamental research. Now, the group has fabricated hBN encapsulated CVD MoS2 monolayers (Figure 1) and analyzed the photoluminescence (PL) spectrum at T = 4 K. What they found was very unexpected: The optical transition linewidth was similar to exfoliated samples [8, 15]. They even observed specific excited states that are only observable for high quality materials [16, 17] and generated large valley coherence and valley polarization [18]. This promises that it is possible to explore spin and valley physics in CVD grown TMD samples.

Counting defects in two-dimensional TMDs

It is not always clear, which type of defect is present in the material [19], however in naturally occuring MoS2 and CVD-grown films, sulfur vacancies can often dominate. Metal vacancies and antisites are more prevailing in synthetic crystals grown by chemical vapour transport (CVT) [2]. The CVD crystals that were used for the study were grown in a modified process in which a Knudsen-type effusion cell was integrated to provide a controlled source of sulfur for the growth [12]. To compare with the exfoliated samples, the researchers prepared also samples from bulk MoS2. They used the so called scotch tape method and an optical microscope to identify monolayers flakes on SiO2 [20]. The samples were transferred to Quantifoil TEM grids and the SiO2 was etched away with KOH and as a result the MoS2 flake is released onto the TEM grid.

Defects can easily be identified in even in the raw wide field-of-view image of the SALVE microscope (Figure 2a). For better visualization, a Fourier-filter can remove the frequencies of the MoS2 lattice (Figure 2b). Small black dots in the lattice indicate a vacancy. In (b), the same area as in (a) is magnified and the vacancies are marked. Figure 2(d) shows an enlarged image of the area marked with a red square in Figure 2(b), where some double sulfur vacancies typically present in the MoS2 samples [12, 21-23], can be recognized.

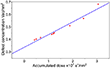

For a more accurate determination of the defect density, the evolution of the defect concentration can be measured as a function of the dose (Fig. 4). In the CVD-grown samples the density was 7.9 × 1013 Vcm-2 . Table 1 shows the different defect densities from each evaluated area. As can be seen, the defect densities do not vary much and most of the values are in the confidence interval. The measured defect density in the CVD samples was therefore of the same order of magnitude as for exfoliated samples [2, 24, 25]. The defect density reported in the literature for MoS2 from naturally occurring bulk is in good agreement with the observations [26, 27].

| CVD MoS2 monolayers (V/cm2) | Exfoliated MoS2 monolayers (V/cm2) |

|---|---|

| 6.9(2) · 1013 | 4(1) · 1013 |

| 9(2) · 1013 | 3.4(9) · 1013 |

| 8.8(7) · 1013 | 4.1(1) · 1013 |

| 3.4(6) · 1013 |

Based on this HRTEM investigation the authors conclude that the CVD-grown monolayer MoS2 possess comparatively high structural quality and therefore high optical quality in emission and absorption experiment. Counting defects in HRTEM is a very good method to measure the structural quality of these new TMD materials after synthesis. The study demonstrates that MoS2 can be used for a wider range of applications thanks to the high quality of the larger area CVD grown flakes. This will surely offer new possibilities for future applications in (opto-)electronics and spintronics.

Resource: Shree, S., George, A., Lehnert, T., Neumann, C., Benelajla, M., Robert, C., Marie, X., Watanabe, K., Taniguchi, T., Kaiser, U., Urbaszek, B. & Turchanin, A. (2019) Accessing high optical quality of MoS2 monolayers grown by chemical vapor deposition. 2D materials, 7, 015011, doi: 10.1088/2053-1583/ab4f1f.

-

Mak K F, Lee C, Hone J, Shan J and Heinz T F 2010 Phys. Rev. Lett. 105 136805

-

Novoselov K S, Mishchenko A, Carvalho A and Castro Neto A H 2016 Science 353 6298

-

Koperski M, Molas M R, Arora A, Nogajewski K, Slobodeniuk A O, Faugeras C and Potemski M 2017 Nanophotonics 6 1289

-

Stier A V, Wilson N P, Velizhanin K A, Kono J, Xu X and Crooker S A 2018 Phys. Rev. Lett. 120 057405

-

Martin E W, Horng J, Ruth H G, Paik E, Wentzel M-H, Deng H and Cundiff S T 2018 (arXiv:1810.09834)

-

Yang L, Chen W, McCreary K M, Jonker B T, Lou J and Crooker S A 2015 Nano Lett. 15 8250

-

Antonelou A, Hoffman T, Edgar J and Yannopoulos S N 2017 J. Mater. Sci. 52 7028

-

Roch J G, Froehlicher G, Leisgang N, Makk P, Watanabe K, Taniguchi T and Warburton R J 2019 Nat. Nanotechnol. 14 432

-

Rhodes D, Chae S H, Ribeiro-Palau R and Hone J 2019 Nat. Mater. 18 541

-

Benameur M M, Radisavljevic B, Héron J S, Sahoo S, Berger H, Kis A 2011 Nanotechnol. 22 125706

-

Lehnert T, Lehtinen O, Algara-Siller G and Kaiser U 2017 Appl. Phys. Lett. 110 033106

-

Algara-Siller G, Kurasch S, Sedighi M, Lehtinen O and Kaiser U 2013 Appl. Phys. Lett. 103 203107

-

Komsa H-P, Kotakoski J, Kurasch S, Lehtinen O, Kaiser U and Krasheninnikov A V 2012 Phys. Rev. Lett. 109 035503

-

McDonnell S, Addou R, Buie C, Wallace R M and Hinkle C L 2014 ACS Nano 8 2880

-

Chuang H-J, Chamlagain B, Koehler M, Perera M M, Yan J, Mandrus D, Tománek D and Zhou Z 2016 Nano Lett. 16 1896

-

Zhou W, Zou X, Najmaei S, Liu Z, Shi Y, Kong J, Lou J, Ajayan P M, Yakobson B I and Idrobo J-C 2013 Nano Lett. 13 2615